Among the numerous innovations, cell-to-pack batteries have arisen as a game-changer, providing a wealth of benefits in compression to traditional battery pack designs.

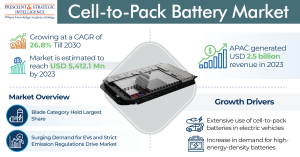

The cell-to-pack battery market is witnessing growth and is projected to reach USD 27,871.9 million by 2030.

Understanding Cell-to-Pack Design

Old-style battery packs contain modules, cells, and a pack structure. The cells are first accumulated into modules, which are then combined into the pack structure, along with numerous motorized and thermal components. This modular method has been the market standard for several years.

The cell-to-pack design, however, removes the requirement for modules by straight integrating cells into the pack structure. In doing so, cell-to-pack design shortens the total architecture, decreases heaviness and size, and advances power density and thermal management.

Key Benefits of Cell-to-Pack Design

Improved Energy Density

By eliminating the transitional module level, the cell-to-pack design permits more compact installations of cells. This optimization directs to advanced power density and therefore augmented battery capacity, allowing longer variety and advanced performance in applications such as electric vehicles.

Reduced Weight and Volume

Old-style module-based designs need added components and materials, like connectors and module casings. CTP design decreases the requirement for such added elements, directing to a lighter and more dense battery pack. This decrease in weight and volume decodes to further effectiveness gains in applications such as electric vehicles, where decreased weight directs to enhanced range and performance.

Improved Thermal Management

The direct addition of cells in a cell-to-pack design permits for advanced thermal conductivity and heat dissipation. Effective thermal management is important for maintaining battery performance, safety, and lifespan. The cell-to-pack method provides more unchanging temperature distribution across the cells guaranteeing ideal performance under numerous working conditions.

Simplified Manufacturing Procedure

The removal of modules rationalizes the manufacturing procedure, decreasing the count of production steps and decreasing the difficulty of assembly lines. This generalization leads to quicker production times, lower manufacturing prices, and augmented scalability for battery makers.

Lower Cost

Cell-to-pack design’s decreased volume, weight, and manufacturing difficulty pay for a lesser overall battery pack price. As battery prices are a substantial reason for the acceptance of electric vehicles and other battery-driven applications, the cell-to-pack method has the potential to quicken the shift toward sustainable power solutions.